Die Casting Process Video: A Comprehensive Guide To Understanding And Mastering The Technology

Die casting is a sophisticated manufacturing process that has revolutionized the production of high-precision metal components across various industries. This article delves into the intricacies of the die casting process, offering an in-depth exploration of its principles, applications, and significance in modern engineering. Whether you're an industry professional, student, or enthusiast, this guide provides valuable insights to enhance your understanding of die casting technology.

As industrial manufacturing continues to evolve, die casting remains one of the most critical processes for producing complex metal parts. With the help of advanced die casting process videos, engineers and manufacturers can visualize and comprehend the step-by-step procedures involved in this transformative technology.

Through this article, we aim to provide a detailed overview of the die casting process, complete with practical tips, expert insights, and reliable resources. Our focus is to ensure that readers gain a comprehensive understanding of the technology, enabling them to make informed decisions in their respective fields.

Read also:Unveiling The Personality Traits Of Those Born On February 13

Table of Contents

- Introduction to Die Casting

- Types of Die Casting Processes

- Components of Die Casting

- Advantages and Disadvantages of Die Casting

- Applications of Die Casting

- Common Materials Used in Die Casting

- Step-by-Step Die Casting Process

- Understanding Die Casting Process Videos

- Best Practices for Die Casting

- Future Trends in Die Casting

Introduction to Die Casting

Die casting is a versatile manufacturing process used to produce complex metal parts with high precision and excellent surface finish. It involves injecting molten metal into a mold cavity under high pressure, allowing the material to solidify and take the desired shape. This method is widely employed in industries such as automotive, aerospace, electronics, and consumer goods.

Why Die Casting is Essential

Die casting offers numerous advantages, including cost-effectiveness, repeatability, and the ability to produce intricate designs. The process is particularly suitable for high-volume production, making it an ideal choice for manufacturers seeking efficiency and quality.

According to a report by Grand View Research, the global die casting market size was valued at USD 27.7 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030. This growth underscores the increasing demand for die-cast components across various sectors.

Types of Die Casting Processes

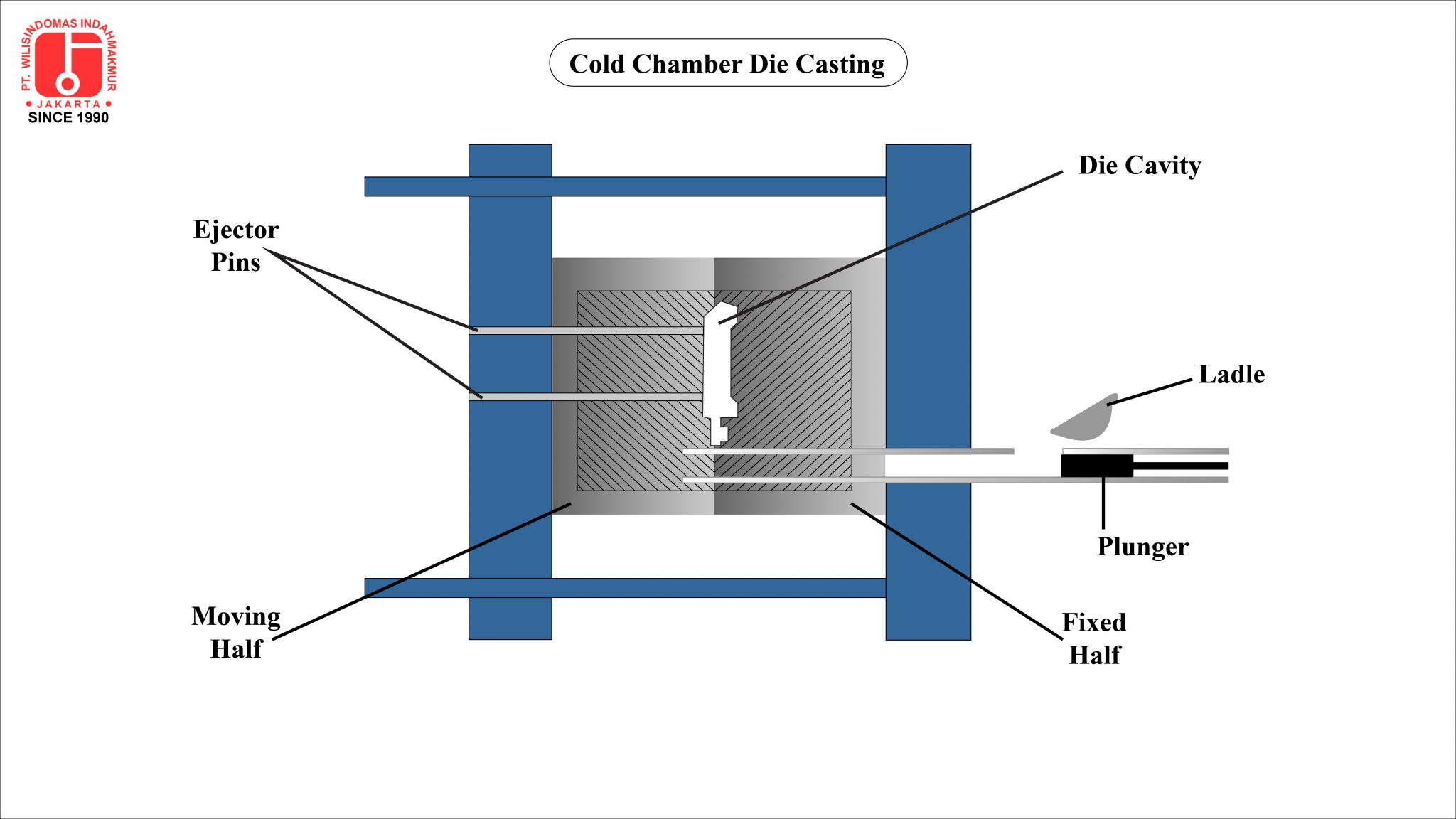

There are several types of die casting processes, each designed to cater to specific requirements and materials. The two primary methods are:

- Hot chamber die casting: Ideal for low-melting-point alloys such as zinc and magnesium.

- Cold chamber die casting: Suitable for high-melting-point alloys like aluminum and copper.

Comparison of Hot and Cold Chamber Die Casting

While both methods share similarities, they differ significantly in terms of application and efficiency. Hot chamber die casting is faster and more economical but is limited to specific materials. On the other hand, cold chamber die casting is more versatile but requires additional steps, increasing production time and costs.

Components of Die Casting

The die casting process involves several key components that work together to ensure successful production. These include:

Read also:Exploring The Chaotic Gore Site A Deep Dive Into Its Origins Impact And Controversies

- Die casting machine: The primary equipment used to apply pressure and inject molten metal into the mold.

- Molds or dies: Custom-designed cavities that define the shape of the final product.

- Metal alloys: Raw materials used for casting, such as aluminum, zinc, magnesium, and copper.

- Trimming tools: Equipment used to remove excess material and refine the finished product.

Importance of Die Design

The design of the die plays a crucial role in determining the quality and accuracy of the final product. Factors such as mold geometry, venting, and cooling systems must be carefully considered to optimize the casting process.

Advantages and Disadvantages of Die Casting

Die casting offers numerous benefits, but it also has certain limitations. Below is a breakdown of its advantages and disadvantages:

Advantages

- High production rates

- Excellent dimensional accuracy

- Smooth surface finish

- Ability to produce complex geometries

Disadvantages

- High initial setup costs

- Limited to specific materials

- Potential for porosity and shrinkage defects

Applications of Die Casting

Die casting is widely used in various industries due to its versatility and efficiency. Some of the key applications include:

- Automotive industry: Production of engine components, transmission parts, and structural components.

- Aerospace industry: Manufacturing of lightweight and high-strength components for aircraft.

- Electronics industry: Fabrication of housings and enclosures for electronic devices.

- Consumer goods: Creation of intricate parts for appliances, tools, and accessories.

Case Study: Die Casting in the Automotive Sector

In the automotive industry, die casting is extensively used to produce engine blocks, cylinder heads, and transmission housings. For example, BMW utilizes advanced die casting techniques to manufacture lightweight aluminum components, enhancing fuel efficiency and performance.

Common Materials Used in Die Casting

Die casting can be performed using a variety of metal alloys, each offering unique properties and applications. The most commonly used materials include:

- Aluminum: Known for its lightweight and excellent corrosion resistance.

- Zinc: Ideal for intricate designs due to its low melting point and high dimensional stability.

- Magnesium: Offers exceptional strength-to-weight ratio and ease of machining.

- Copper: Provides superior electrical and thermal conductivity.

Material Selection Criteria

When choosing a material for die casting, factors such as mechanical properties, cost, and environmental impact must be considered. For instance, aluminum is often preferred for automotive applications due to its lightweight nature and affordability.

Step-by-Step Die Casting Process

The die casting process involves several critical steps, each contributing to the final product's quality and performance. Below is a detailed breakdown:

- Preparation: Cleaning and lubricating the die to ensure smooth operation.

- Melting: Heating the metal alloy to its molten state in a furnace.

- Injection: Injecting the molten metal into the die cavity under high pressure.

- Cooling: Allowing the metal to solidify and cool within the mold.

- Ejection: Removing the solidified part from the die.

- Trimming: Cutting off excess material and refining the component's surface.

Key Parameters in Die Casting

To achieve optimal results, several parameters must be carefully controlled during the die casting process. These include injection pressure, mold temperature, and cooling time. Proper management of these variables ensures the production of high-quality components.

Understanding Die Casting Process Videos

Die casting process videos serve as valuable resources for visual learners and professionals seeking to enhance their understanding of the technology. These videos provide step-by-step demonstrations of the process, highlighting critical aspects such as mold preparation, metal injection, and part ejection.

Benefits of Watching Die Casting Process Videos

- Visual representation of complex procedures

- Enhanced comprehension through real-world examples

- Opportunities to observe best practices and troubleshooting techniques

Recommended Die Casting Process Videos

Several reputable platforms offer high-quality die casting process videos, including YouTube, LinkedIn Learning, and industry-specific websites. When selecting a video, ensure it is produced by a credible source and covers all essential aspects of the process.

Best Practices for Die Casting

To achieve optimal results in die casting, manufacturers must adhere to best practices that ensure quality, efficiency, and safety. Below are some key recommendations:

- Regularly inspect and maintain die casting equipment to prevent breakdowns.

- Implement strict quality control measures to identify and address defects promptly.

- Invest in employee training programs to enhance skills and knowledge.

- Adopt sustainable practices to minimize environmental impact.

Quality Control in Die Casting

Quality control is a critical component of the die casting process, ensuring that all components meet specified standards. Techniques such as non-destructive testing (NDT) and dimensional inspections are commonly used to verify product quality.

Future Trends in Die Casting

The die casting industry is continuously evolving, driven by advancements in technology and shifting market demands. Some of the key trends shaping the future of die casting include:

- Automation and robotics: Increasing adoption of automated systems to enhance productivity and reduce labor costs.

- Sustainability initiatives: Growing emphasis on eco-friendly practices and materials.

- Advanced materials: Development of new alloys with improved properties for specific applications.

Conclusion

Die casting is a vital manufacturing process that continues to play a significant role in modern engineering. By understanding the principles, applications, and advancements in die casting technology, professionals can harness its full potential to meet industry demands. We encourage readers to explore die casting process videos and other resources to deepen their knowledge and stay updated with the latest trends.

We invite you to share your thoughts and experiences in the comments section below. Additionally, feel free to explore our other articles for more insights into manufacturing and engineering topics. Together, let's drive innovation and excellence in the world of die casting!

Article Recommendations

![The Die Casting Process, Ingots, & Aluminum Casting [Videos]](https://qualityinspection.org/wp-content/uploads/2019/08/AllabouttheDieCastingProcessIngotsandAluminumCastingVideos.jpg)